How we designed the Ryka

Handsome by accident.

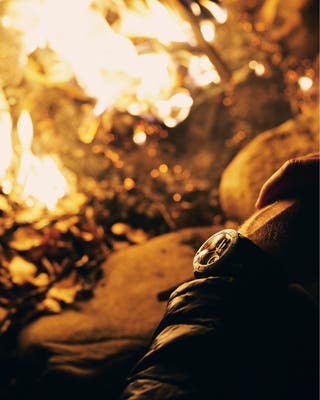

Let's be honest. Not all of our watches would survive in the wild. They're kinda like people that way – impressive in a social setting, but they wouldn’t do well rock climbing in Norway. The Ryka is not your average watch. We didn't design it for the average man, either.

We have a lot of gorgeous watches. With the Ryka, we wanted to do something different. We wanted to create a watch that'd survive almost anything. A watch you could take on a mud run, rinse afterwards, and it'd be good as new. A watch you could leave to your grandson after you pass. We wanted to design a watch so rugged, so strong, so durable you could run it over with a tank. Don't get us wrong, you'd still smash the watch, but for a split second before it went ‘splat,’ you'd have a moment of doubt. All the other things, though, we accomplished.

But how do you go about designing a watch that'll take anything you throw at it and emerge unscathed? That's the story of how we designed the Ryka.

It starts with the movement

A watch is only as strong as its weakest cog.

What's the point of creating a waterproof and scratch-resistant watch if the minute hand falls off when you bump into a wall or it starts running at 26 hours a day because you left it in direct sunlight for a few hours? The movement is always the most important feature of any watch and every other feature would be pointless if the movement wasn't carefully selected for the right properties. Many watch designers seem to forget this.

For the Ryka, we chose the ultra-reliable and robust Miyota Cal. 6S21 chronograph. It's not just a fantastically reliable piece of Japanese engineering, but the chronograph feature allowed us to add something to the Ryka's design that was at the very top of our "most desired extras" list... a stopwatch.

There are simply so many scenarios in rough situations where a stopwatch would come in handy – from estimating the distance of a thunderstorm while camping, to safely cooking game in the wild, to timing yourself while preparing for the Tour de France... a chronograph turns the Ryka from a rugged accessory to a survivalist's tool.

Making a watch virtually indestructible

It's not... but it might as well be.

Looking at the Ryka, holding it in your hand, feeling its weight, you might think it's indestructible. Legally though, we're not allowed to say that. But how do you make something so small and intricate so tough?

Apart from regular battery changes, crystal replacement is one of the most common tasks watchmakers face on a daily basis. They rarely have to change sapphire crystal, though.

Sapphire Crystal

We've known how to make synthetic diamonds since 1879. The first lab-grown ruby was made in 1902 and sapphire followed soon after in 1909. Gemstones are a lot harder than glass.

Hardness determines how easy a surface is to deform and scratch, and it’s measured using the Vickers scale (HV).

- 10000HV Diamond – the hardest material known to man.

- 2200HV Sapphire glass – the hardest material used for making watch crystals.

- 800HV Hardened mineral glass – the most common type of glass used for watch crystals.

- 500HV Hesalite glass – mostly used in older, less expensive quartz and digital watches.

- 30-80HV Iron – for context.

The Ryka features a double-domed sapphire crystal, and you’ll be hardpressed to find stronger, more durable watch crystals. Flat sapphire crystal is relatively easy to make, but domed - let alone double-domed - is a lot more complex and therefore expensive. However, the domed shape makes the crystal structurally stronger, allowing it to survive greater pressure (f.ex. while diving) or absorb shock better (f.ex. when you're doing manly things with your manly man hands).

A domed shape on one side will warp your view of the watch, making it difficult to read except from one specific angle. With a dome on both sides, that warping is cancelled out. Anti-reflective coating is then added to make the sun's glare a non-issue.

The Case

The face of the watch is what you'll be looking at, but the case is what you manipulate. It was important to us that the watch was easily readable under any condition, whether it be at 100 m underwater or 8000 m above sea level. That's why we went with the classic diver's watch layout with thick arms and strong accents featuring Swiss lume for bright nighttime reading.

The bezel is rough and the buttons and crown are too. This is to give you full use of the watch without taking your gloves off. Snowboard with the Ryka strapped to the outside of your glove and time yourself from the top of the hill to the bottom. The watch back and crown are both screwed on rather than pressed, for extra durability and solidity.

PVD coating

Go to your local hardware store and look for steel drill bits. Some of the higher-end ones will have a golden tone to them. That's titanium nitride, and it's put there to protect the bit from what it's drilling into – other steel.

The process of PVD coating steel involves superheating titanium nitride to its plasma state and shooting it at the object inside a vacuum chamber. Compared to most surface treatments, it's environmentally friendly. No baths filled with chemicals that the object is dipped into and no leftover paint being pumped into water supplies.

This process reduces friction and makes the drill bit a lot tougher and more durable. And if PVD coating doesn't flake off a drill bit that's making its way through solid steel, it's not going to flake off your watch. Adding tiny amounts of pigment to the mix allows us to make rose gold and silver tones, as well as rainbow, blue, black, copper, coffee, gunmetal-grey and other colours.

Lower friction means items that come into contact with the steel's surface are more likely to slide off rather than catch on and leave a permanent mark. This combination of low friction, hardness, and toned shine makes PVD coating perfect for creating lasting, durable surgical-grade stainless steel jewellery and accessories of all kinds. The fact that it's far less expensive than precious metals is just an added bonus.

The Strap

Everything about the Ryka is designed from a functionality-first approach. The single-loop webbing of its US military strap is extremely strong, breathes nicely, is made of non-absorbant nylon, and is easily replaceable – it simply loops under the spring bars on the watch case. You can even toss it in with the laundry after a particularly messy adventure while you give the case itself a thorough scrubbing.